Packing material of coated steel plate:

(1) Protective material: wood, metal plate, fiberboard, plastic or other suitable materials.

(2) Protective packaging materials: kraft paper, ordinary paper, vapor phase anti-corrosion paper, greaseproof paper, plastic film, etc.

(3) Packing strap: narrow steel belt or steel wire, etc.

(4) Protective coating: various preservatives or grease-like materials.

(5) Anti-deformation materials: edge guard angle iron, side guard plate, coil sheath and coil end cover plate.

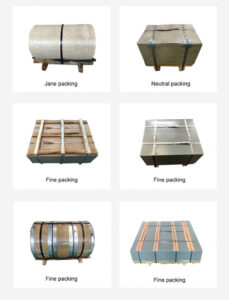

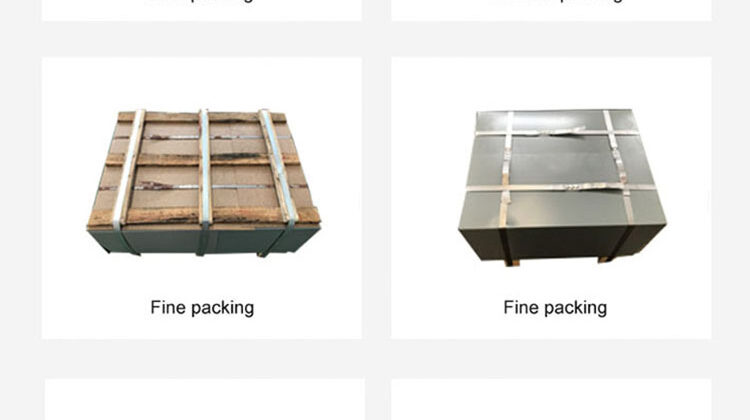

Packaging method of coated steel plate

After the coated steel sheet comes out of the post-coating cooling process, the entire coating process is basically completed. Strip steel enters the coiling process through the exit section of the production line. The exit section of some laminating units has the function of vertical and horizontal shearing, so that the steel plate products can be directly cut into strips or cut to length into the packaging process of the finished product. The task of packaging is to tie the stacked steel plates and the coiled strip steel tightly to prevent damage, pollution or rust.

The form of packaging is divided into plate-shaped packaging and roll-shaped packaging. Any strip that directly enters the cut-to-length flying shear process through the export section belongs to plate-shaped packaging. If it is directly reeled or entered into slitting reeling, it is a roll package. The packaging of finished products is also part of the quality control work of coated steel plates. Because the quality of the packaging is not good, the product will have quality problems in terms of corrosion and deformation, which greatly affects the processing performance and use performance of the product. Therefore, the packaging effect should ensure that the product is in It will not be loose, damp, deformed or damaged during transportation and storage. my country has standard requirements for the packaging forms and methods of coated steel sheets. The following describes several packaging forms of coated steel sheets. The specific operations should be implemented in accordance with national standards.

Roll packaging

Roll packaging can be divided into vertical packaging and horizontal packaging according to the direction of the roll eye position, and can be divided into tray packaging or non-tray packaging according to whether a tray is configured. The wooden bracket used for packaging depends on the roll diameter, and the bracket material must be thick. The packaging materials are the same as the plate packaging. Pay attention to use more than one layer of protective packaging materials. Some color coated steel plate production lines are equipped with special packaging lines. This line has a large investment and a large area, but has high efficiency. It is generally arranged in a centralized manner for multiple shearing units. On average, it can automatically pack one every 15s. Roll. A packaging worker can complete the packaging task of 60 rolls per hour, which is generally configured for large-scale coated steel plate production lines.

Plate packaging

Packaging preparation

In order to reduce the probability that the boxed plate is easily deformed due to transportation and lifting, the boxed thin steel plate packaging should use skids or wooden brackets. The skids are divided into longitudinal skids and horizontal skids. The width and length of different thin steel plates should be matched Suitable number of skids.